Tape measures are a staple in toolboxes worldwide, used by professionals and DIY enthusiasts alike. Despite their ubiquity, many are unaware of one of their most important features: their moving tip. This seemingly faulty component often leads users to believe their tape is broken or defective. However, this design is intentional and serves a vital function. Understanding the purpose of this feature can improve measurement accuracy and the overall user experience.

The common misconception about free tipping

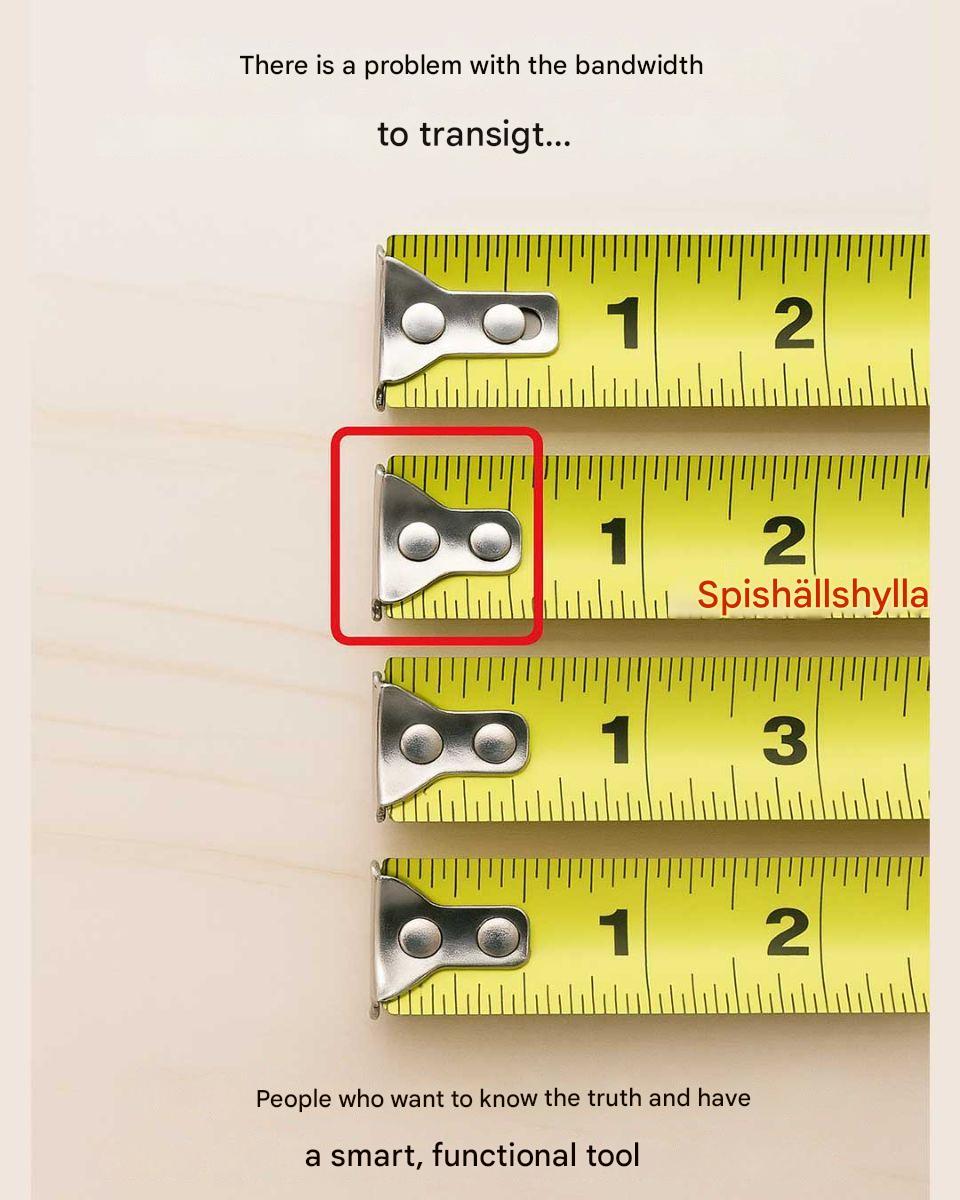

When you first notice the tip of a tape measure moving, you often assume it’s a manufacturing defect. The tip, which seems to wobble or move slightly, can be mistaken for a sign of wear. This misconception is widespread because most users are unaware of the technical design of this product. They may therefore attempt to fix the “problem” themselves, potentially compromising the tape’s functionality.

Understanding the design of a measuring tape

The design of the tape measure is a technical feat combining simplicity and functionality. It consists of a flexible metal strip that is easy to wind and unwind. Precise markings on the strip allow for accurate measurements. A movable point, often made of metal, is attached to the end of the strip. This point is designed to move slightly, an essential feature for ensuring accurate measurements, whether the strip is used to measure interior or exterior dimensions.